Case Studies

What is a Full Inspection and When Should You Use It?

Product Inspection

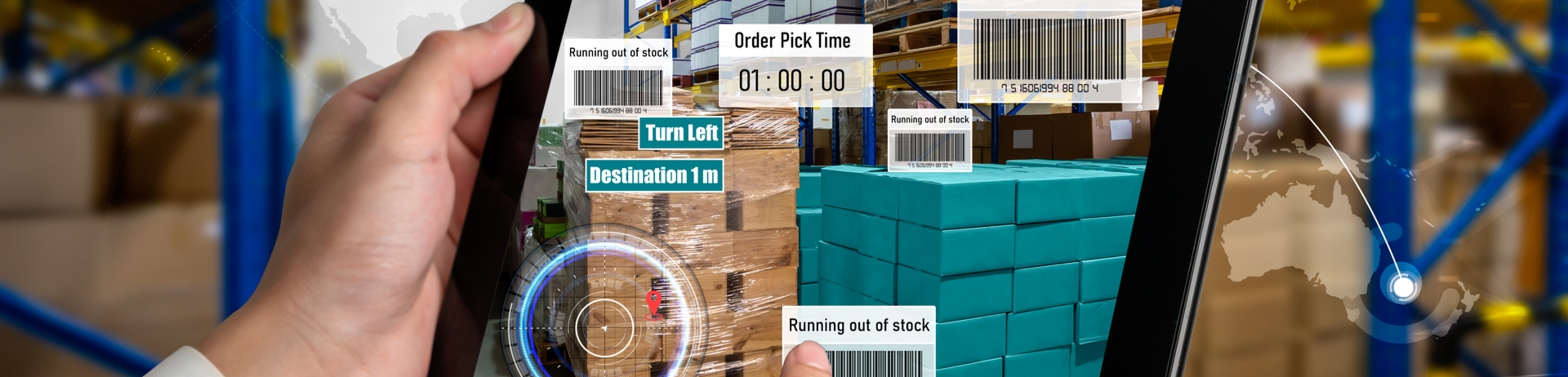

Third-Party Product inspection is essential in product sourcing

With the migration of supply chain and production capacity from the developed countries to the developing regions, the sourcing strategies for businesses must be adapted to accommodate the new normal. Traders and e-commerce sellers who import manufacturing merchandises nowadays must somehow source from China and other Asian countries. Instead of buying from local suppliers that the buyers can send inhouse QC teams to inspect the products, cross border purchases are not that easy and hiring third-party inspection companies to conduct inspections are essential. Otherwise, they may risk their products being shipped out without quality inspections. Accepting shipments without quality inspections are just like gambles while prudent businesses would never take part in.

What is a full inspection?

For trader who purchases end products from manufacturers, the most popular product inspection is pre-shipment inspection or final random check. By inspecting a random sample of the order based on the AQL sampling method to determine if accepting or rejecting the order. On the other hand, full inspection is to inspect every item of the order and any defective items are identified and removed. The inspection results in a defect free order. Comparing with the AQL inspection that inspects only a selected size of sample, full inspection requires more time and is more expensive. In most situations, a low level of defective rate may not cause big deals, AQL inspection can serve the quality control very well in most purposes. However, in some cases, full inspection can serve very well a particular quality control need.

When should a buyer use full inspection?

It is more time consuming and costly by checking all items of a shipment. However, there are many cases that the time and money are well spent to obtain a defect free shipment.

1) Luxury products/Luxury brands

Many luxury products are not saleable if they are defective. Defective products if appear in the market can hurt the image and reputation of a luxury brand greatly. Full inspection checks every item of the order so that only the good quality items are shipped in the order.

2) Products with health or safety risks

Some products such as toys with movable parts that can create safety hazards. Full check may be required by regulations or by the buyer voluntarily to prevent the high product liability.

3) Handle excessive defective rate

In many cases, the order on a supplier may not pass the AQL inspection. However, the buyer may still want to buy the products from the same supplier. As switching to a new supplier may not be possible time wise. The buyer may initiate a full inspection to make up a new defect free order instead.

4) The order size gives no different in cost between full vs AQL inspection

Sometimes, an order size may make no different between full inspection and AQL inspection, then it is always better to use a full inspection as it generates defect free order.

Conclusion

Production inspection is essential in products sourcing. Traders and importers buy end products from China and Asia suppliers, the most popular type of product inspection is the pre-shipment inspection. It can be the final random inspection or full inspection. Final random inspection is cost-effective and serves the quality control needs in most situations. Full inspection needs more time and therefore more costly. Traders and importers should assess their quality control requirements to choose the suitable solution.

- The Importance of China Product Inspection Service in Ensuring Quality Control

- Value of Quality Control Inspections for Manufacturers

- Maintain the Product Standard – Take the Help of the Quality Control Company

- Vietnam Product Inspection: Enhance the Overall Brand Quality

- Reason for hiring inspection services for manufacturing products in China

- May 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- February 2018

- December -0001

- AQL inspection service

- Asia quality control

- Asia Quality Inspection

- China Product Inspection Services

- Factory Audit

- Inspection Service in China

- Pre-Shipment Inspection

- Product Inspection

- Product Inspection in Vietnam

- Product Inspection Service

- Production inspection

- Quality Control Company

- Quality Inspections

- Third Party Inspection

- Vietnam inspection