Initial Production Check

What is Initial Production Check?

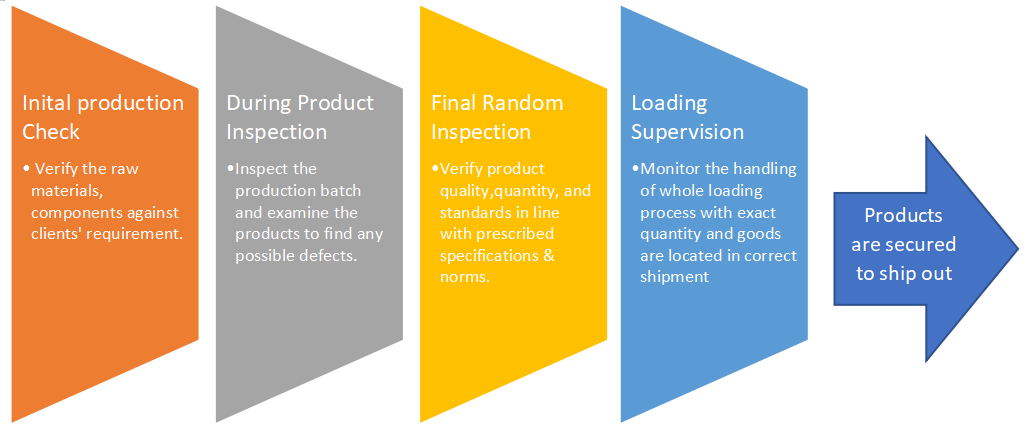

Initial Production Check (IPC) carries out when the production is at the early stage to identify if the correct raw materials, components are used at the stage of components are used when product start. This process involves the inspection of raw materials before the start of the production process. It also involves the verification of materials ordered by the factory.

A preliminary check of materials and methods to be used in your production would be the first step in ensuring the quality of your products. Before production, many things need to prepare, set up and calculate. Even though all the things are prepared and set on-site, there may be something unforeseen and go out of expectation, ruining the whole shipment quality. IPC can act as an early warning signal to the quality issues by identifying the potential flaws of materials, components procedures, rectifying the potential issues without turning into an inevitable quality crisis.

Benefit of IPC –

- Act an early warning signal to verify potential defects.

- Identify and rectify defects before mass production.

- As a preventive measure placed before production.

- Take control of the product quality from the raw materials, procedures.

- Any non-nonconformity is immediately reported to avoid delay in shipment.