Initial Production Check

Case Study - Decisive Differences in Barcodes and Model Numbers

Third Party Inspection

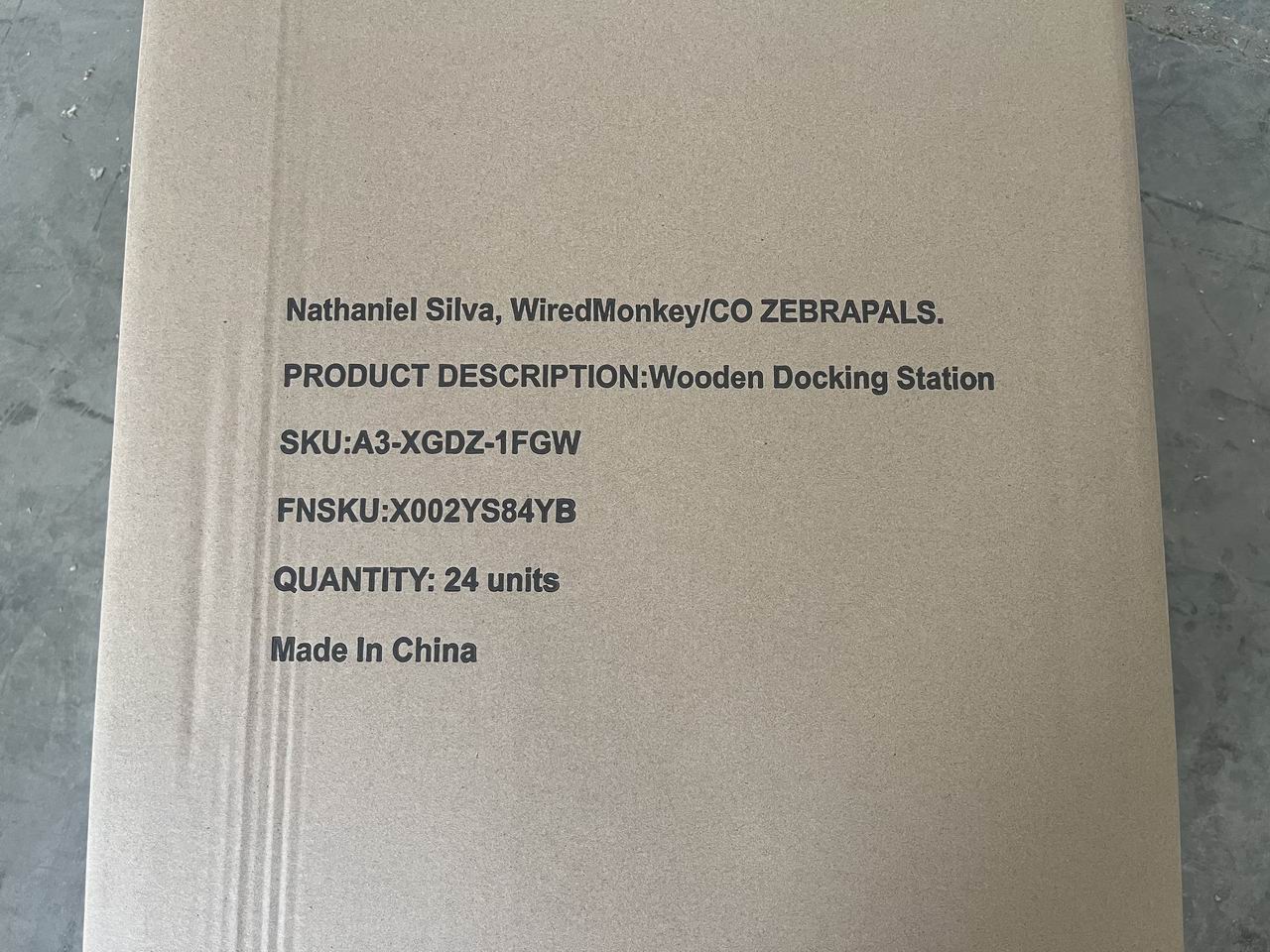

During product inspections, cross-referencing product barcodes and model numbers is of paramount importance. In this case, we were tasked with inspecting two varieties of desktop organization stands, but the client had not provided the necessary packaging and barcode data. Consequently, our inspector had to rely on the SKU and FNSKU data printed on the box, but this presented an unexpected challenge.

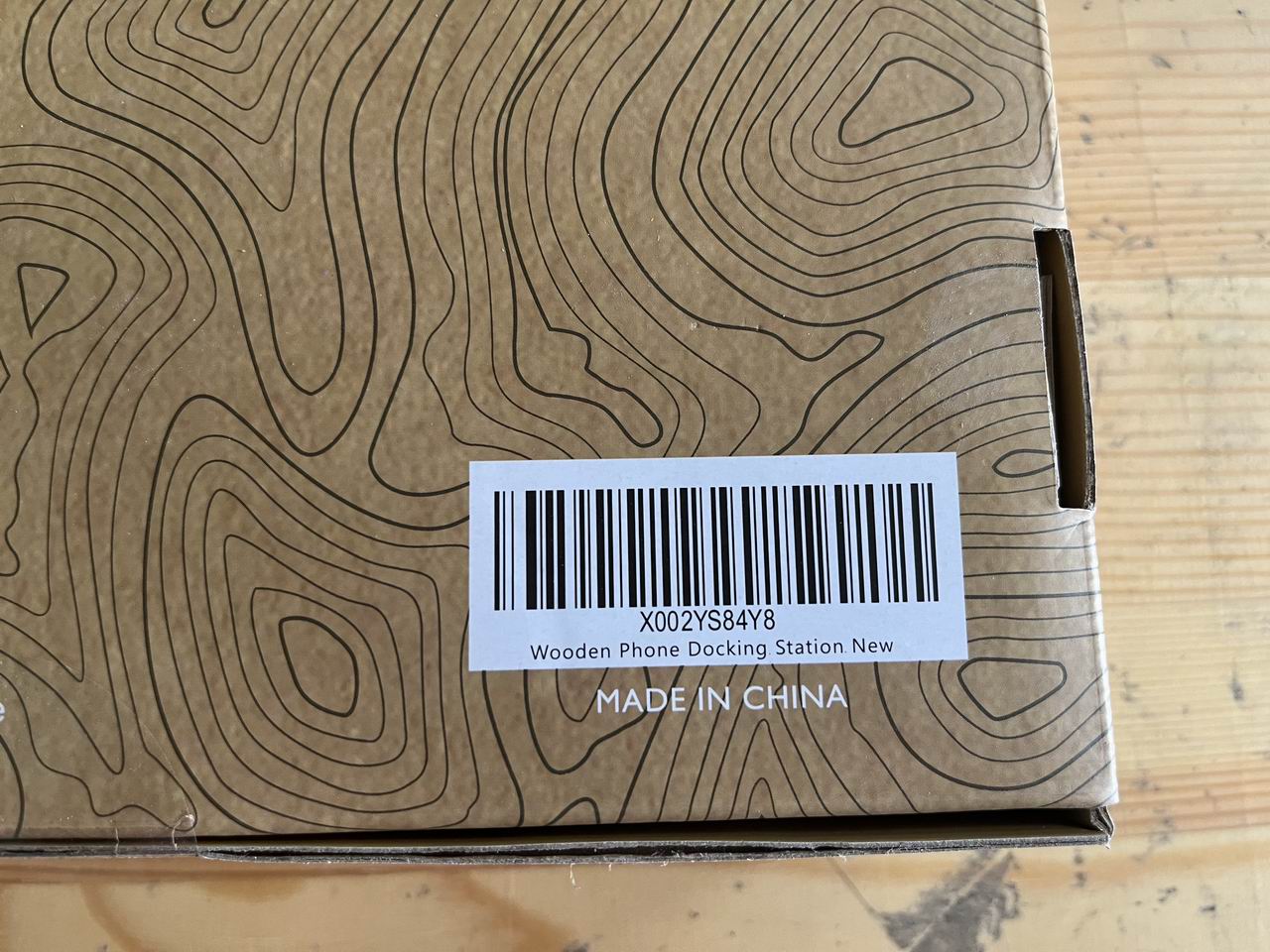

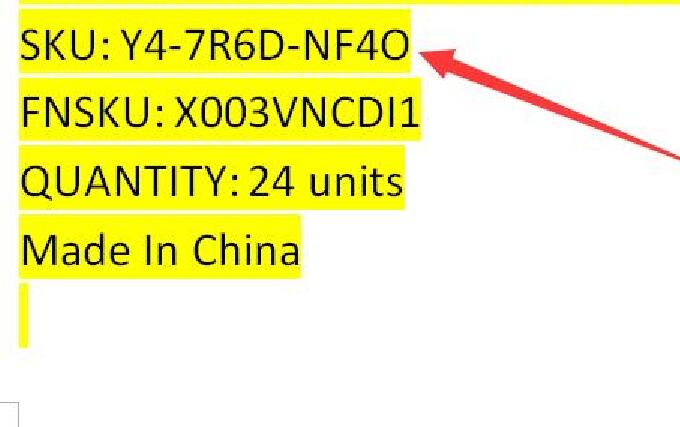

Firstly, one product's barcode on the packaging should have ended with the letter "B" (photo 1), but it had mistakenly been printed as the number "8" (photo 2). In another instance, an FNSKU code was expected to contain the letter "O" (photo 3), but it was erroneously printed as the number "0" (photo 4).

While these may seem like minor discrepancies, they can have far-reaching impacts on the product's logistical processes. Even a single incorrect character or digit can lead to misclassification, hampering inventory management and complicating product tracking. These seemingly small errors can disrupt the entire supply chain, causing logistics issues and potentially leading to sales errors or customer satisfaction problems in the retail environment.

Hence, the discovery of such minute issues, though seemingly trivial, is indeed significant. They contribute to ensuring the accurate identification of products, ultimately reducing logistical confusion and enhancing the precision of sales, all while safeguarding the interests of our clients. This case underscores the role of inspectors as professionals committed to scrutinizing every detail, thereby ensuring product quality and customer satisfaction, while minimizing potential confusion and errors.

- Case Study - Attention to Detail and Product Integrity - Hook Design Oversight

- Case Study - Attention to Detail - Snap Button Issue in Skiwear Accessories

- Case Study - A Tightening Resolution

- Production Inspection in Vietnam: Why Hire Third-Party Inspection?

- Case Study - Quality Control in Wooden Products before Shipped from Guangdong

- Factory Inspection

- Case Study - Vigilance and Swift Detection: Fake Cartons Incident

- supply chain audit post