Initial Production Check

Case Study - Discrepancies in Pet Water Dispensers

China Product Inspection Services

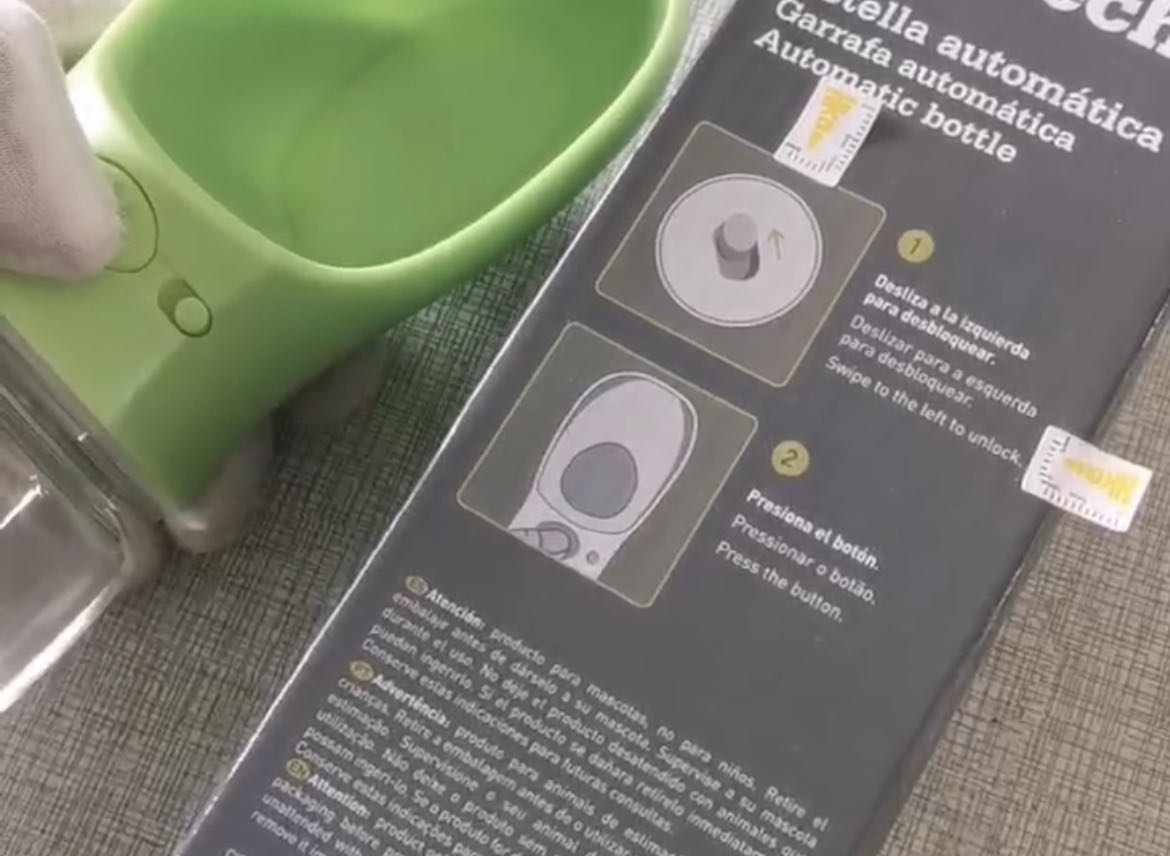

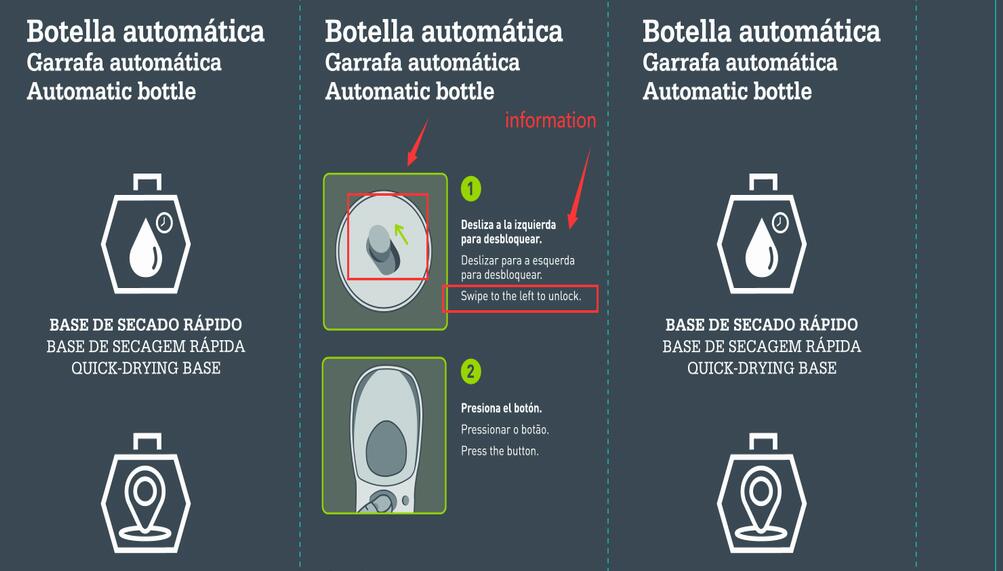

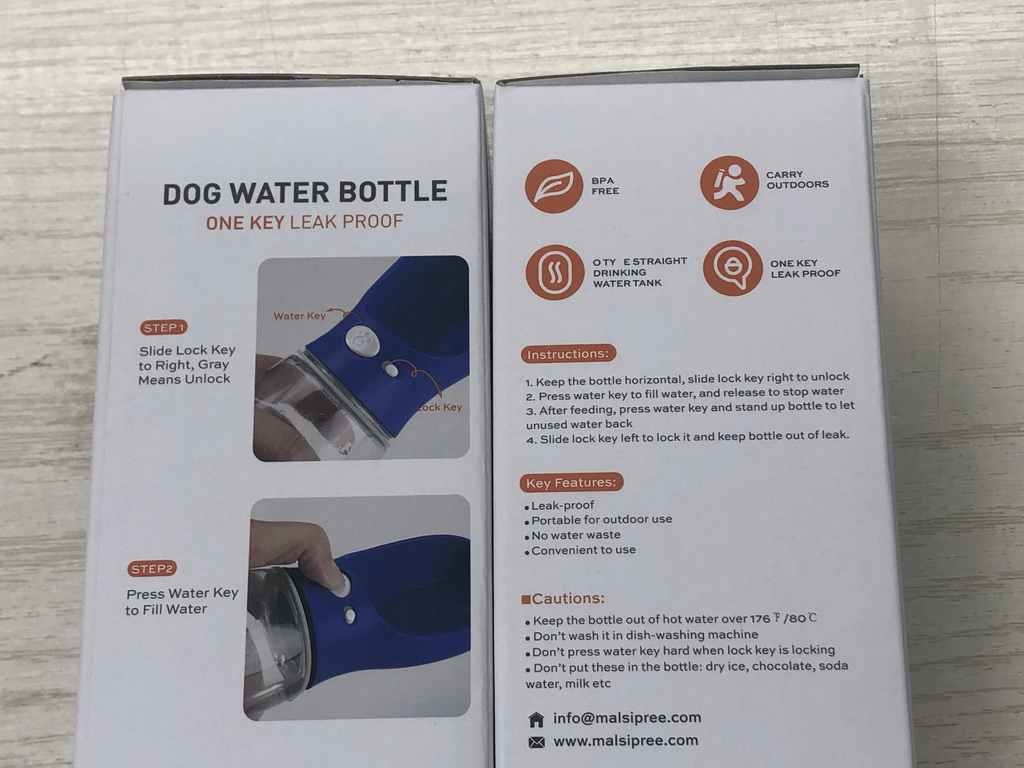

In cases where detailed inspection data isn't provided by the client, the product manual and packaging become crucial reference materials for comparing product details and functionalities. In this recent inspection, we focused on pet water dispensers featuring a button and a locking mechanism. During the assessment, the inspector noticed a discrepancy when comparing the instructions printed on the packaging with the actual product functionality.

The instructions on the packaging indicated that turning the locking button to the left was the direction to unlock, consistent with the information provided by the client. However, the real product functionality required turning the locking button to the right to unlock and release water. This disparity could lead to customer confusion regarding the correct usage of the product, potentially causing a series of issues.

We promptly reached out to the factory to verify the situation. The factory responded, explaining that for all the products they manufactured, turning the locking button to the right was the correct way to unlock and dispense water. The packaging design was provided by the client , and the factory had not previously noticed this issue. Further comparison revealed that other clients' products also featured instructions indicating a rightward turn for unlocking and water release.

The factory stated that they would address this difference with the client but had no plans to alter the product. Regardless of whether the error stemmed from the client or the factory, our responsibility remains to ensure product quality and adhere to the quality standards that meet customer expectations. This case underscores the critical importance of packaging and manuals for verifying product details when comprehensive inspection data isn't provided. It also emphasizes our role as inspection professionals to identify and report any discrepancies to maintain product quality and customer satisfaction.

- Case Study - Attention to Detail and Product Integrity - Hook Design Oversight

- Case Study - A Lesson in Bamboo Fencing Inspection

- Case Study - Quality Implications of a Pet Chew Toy with Sound Function

- Case Study - Unveiling Hidden Printing Errors: How Vigilant Quality Control Enhances Product Integrity

- How Product Inspection Can Be Benefitting In Every Way?

- How Our Quality Control Audits Benefit Your Firm

- supply chain audit post

- Case Study - Attention to Detail - Snap Button Issue in Skiwear Accessories