Initial Production Check

Case Study - Discovered Hangtag Print Residue during Pre-shipment Inspection

Asia quality control

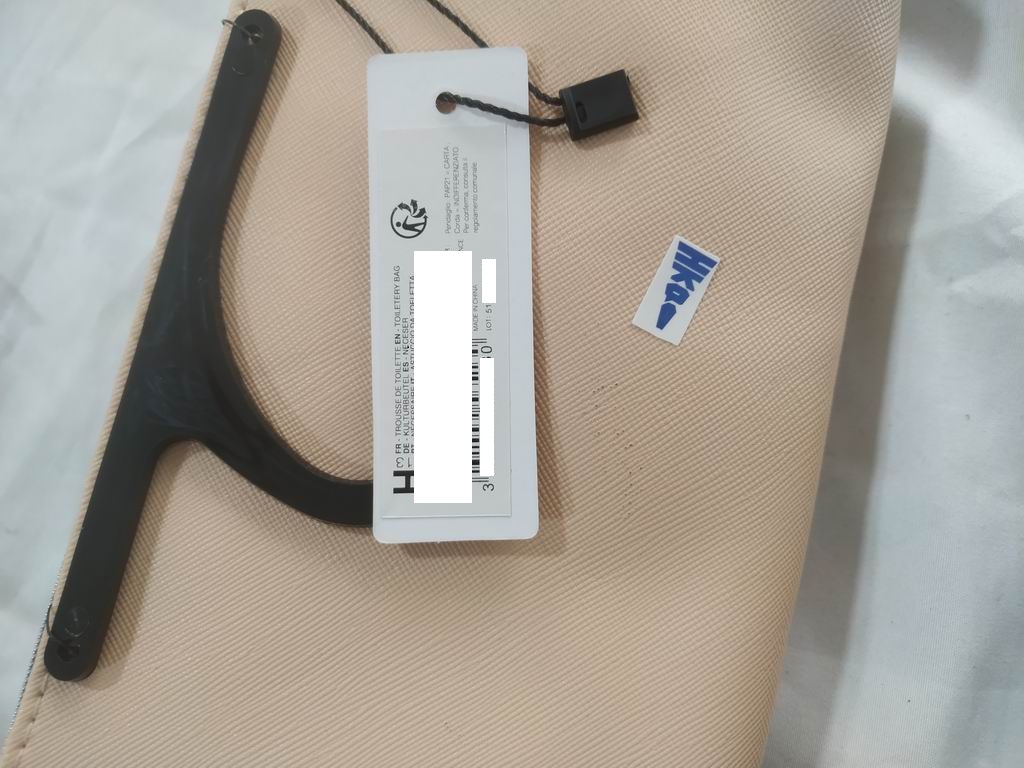

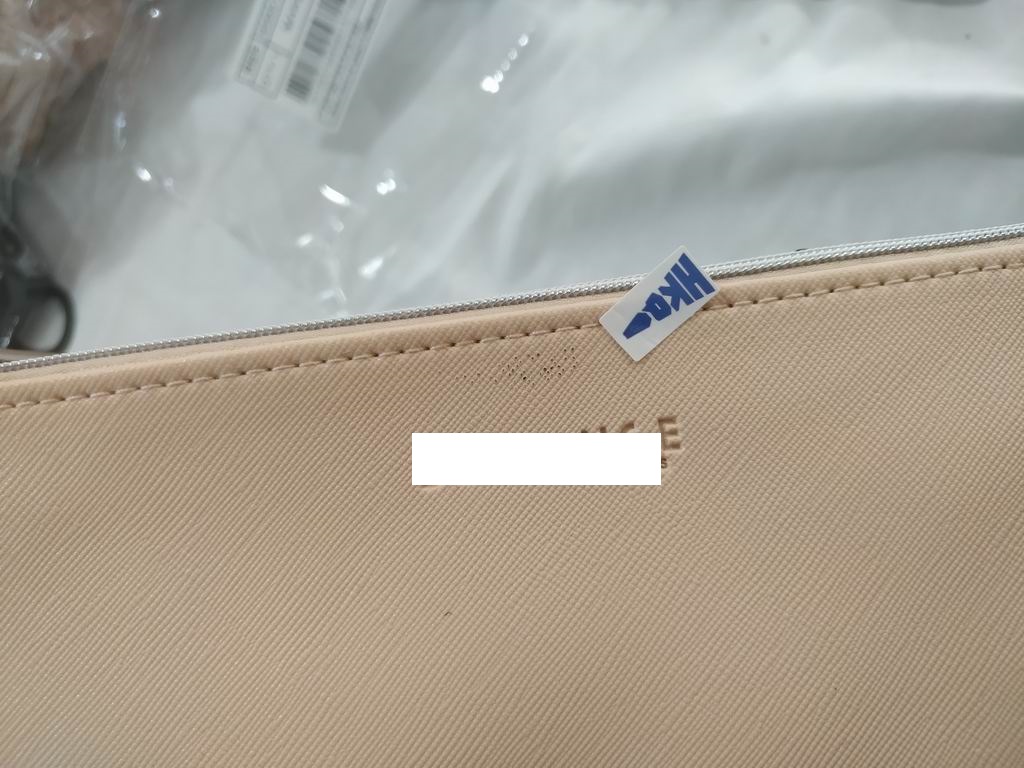

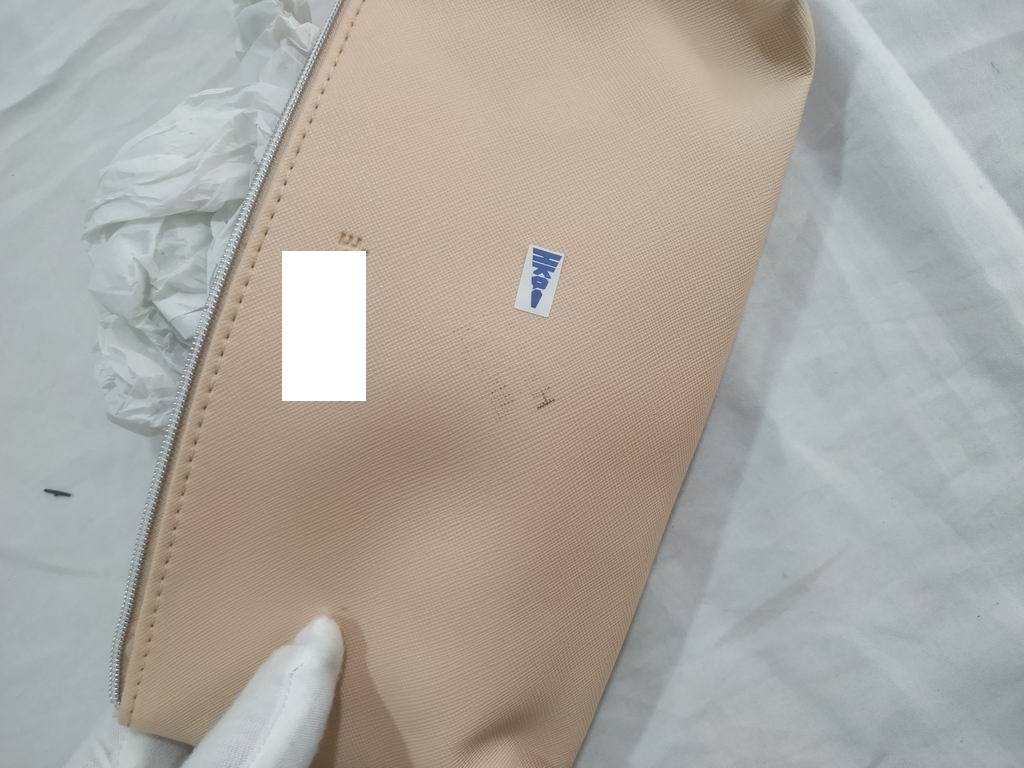

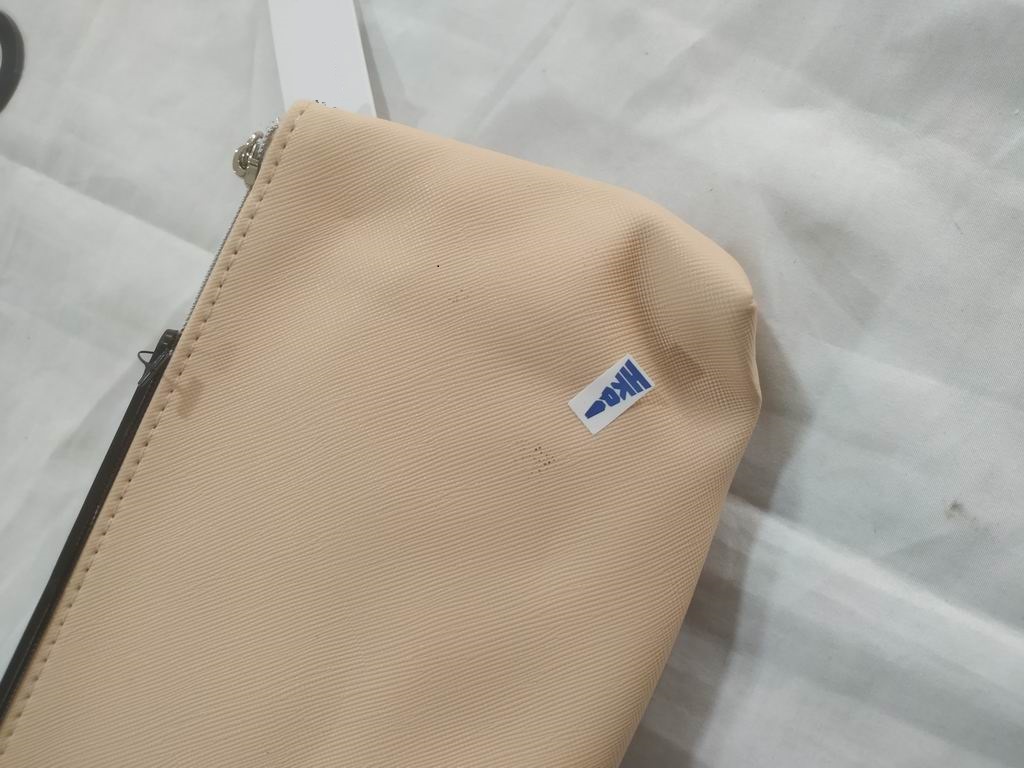

In this case, we discovered a noteworthy issue while examining pink-colored products during product inspection. The hangtags appeared to be adhered to the products, leaving behind black residues on the packaging when removed. These residues, identified as discolored print from the hangtag stickers, could be wiped off manually. Further inspection led the inspector to conclude that the brown residues resulted from the discoloration of the hangtag print. The absence of tissue paper isolation between the hangtag and the product facilitated the transfer of black print onto the product surface.

Upon notifying the factory of this issue, they decided to implement tissue paper isolation for both the product and hangtags to prevent print discoloration residues. This improvement not only contributed to maintaining the cleanliness of the product's appearance but also mitigated potential negative impacts on the product's visual appeal caused by the hangtag.

This case underscores the practical necessity of employing isolation paper in product packaging. Our goal is to assist factories in enhancing their production and packaging processes, elevating the overall quality and appearance of products through professional advice. Through such improvements, we help clients avoid potential quality issues and associated risks of claims.

This experience also highlights the significance of inspectors in examining product appearances. With our continuous scrutiny of products, we are committed to providing clients with comprehensive quality assurance. By introducing small yet crucial improvements in the manufacturing process, we ensure that the final product not only meets standards but also gains trust in the market from both clients and consumers. Our inspection services go beyond issue identification; they serve as robust support in quality control, assisting clients in ensuring their products are in optimal condition at every stage.

- Cost-effectiveness of Third-party Inspection Services

- Case Study - Ensuring Precise Product Compatibility in Handcrafted Artifacts

- How Product Inspection Can Be Benefitting In Every Way?

- The Inside Scoop on HK Q.C. Center Acceptable Quality Limit Inspection

- Quality Control Audit

- Case Study - Precision Matters in Plush Toy Checks

- The Importance of Quality Control in Asian Industries

- Case Study - Manufacturing Discrepancy in Pet Ladders