Initial Production Check

Case Study - Ensuring Precise Product Compatibility in Handcrafted Artifacts

Asia quality control

In the world of quality checks, paying close attention to details matters, especially for handcrafted items that might have slight differences in size. Ignoring these differences could lead to things not fitting together properly.

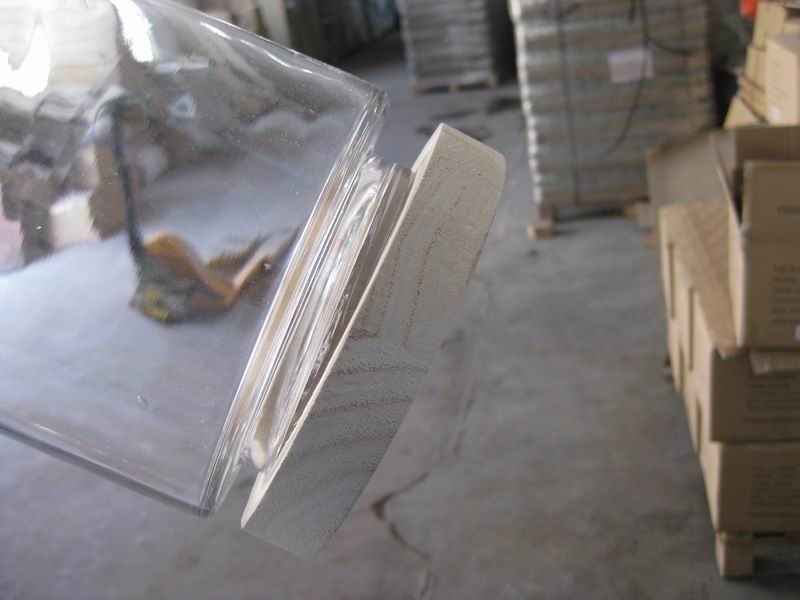

This case is about a hand-blown glass vase with a wooden base (photo 1). There were 8,400 sets of these, spread across 2,100 boxes. During our quality check, we carefully matched each glass vase with its wooden base. But we found a problem – many wooden bases didn't fit well with the bottom of the glass vase (photo 2-4).

When we asked the factory about this, they told us they only make the glass vases. The wooden bases come from a different place. They measured just one pair of vases to make the bases fit. After the bases arrived at the factory, they only tested a few of them to see if they fit before packing them.

Because the glass vases needed delicate packaging, the wooden bases weren't put on them before packing. Instead, the vases were protected with foam, and the wooden bases were placed on top. The workers were paid based on how many things they made, so they didn't check each set to make sure everything fit (photo 5).

The glass vases have special shapes, so they're made by hand to avoid using molds. This can make their sizes a bit different. Also, wood can change shape a little because of temperature and humidity. The factory didn't think about these changes when they made the vases and bases, so there was a problem.

Clearly, something needed to be fixed. With 2,100 boxes to go through, the factory had to open each box and make changes. Even though it was a lot of work, the factory was thankful we found the problem in time. This stopped bigger problems when the products would have gone to customers.

This case shows how important it is to pay attention to every detail when making handcrafted items. It also shows that we're committed to making sure the things we check are of the highest quality.

- Case Study - Quality Control and Honesty - Exposing the Sticky Situation

- Case Study - Ensuring Precise Product Compatibility in Handcrafted Artifacts

- Case Study - The Significance of Quality Control and Effective Communication: Unveiling the Story Behind Transparency Issue

- Quality Control Audit

- Case Study - An Enduring Date Mistake found from Quality control

- The Importance of Quality Control in Asian Industries

- Get the Most from Our Garment and Toy Audits and Inspections

- The Inside Scoop on HK Q.C. Center Acceptable Quality Limit Inspection